The Launch Latch

Design and prototype of a remote propellant fueling system

Overview

The Wisconsin Space Program (WiSP), a student-led initiative at the University of Wisconsin–Madison, aims to advance amateur rocketry and provide hands-on aerospace engineering experience. As part of its mission, WiSP is developing a liquid-fueled rocket using isopropyl alcohol (CH₃CHOHCH₃) as a fuel and nitrous oxide (N₂O) as an oxidizer. The design emphasizes efficiency and safety, particularly in the critical fueling and disconnect processes, to enable safe operation under demanding conditions.

Nitrous oxide, managed above its saturation pressure of approximately 750 psi to optimize density and utilize its self-pressurizing ability, presents unique challenges in fueling. Unlike isopropanol, which can be loaded manually, nitrous oxide requires remote handling due to the highly pressurized nature of the oxidizer tank and safety concerns. Additionally, the oxidizer must be supplied just before launch to minimize vaporization and venting losses. These requirements necessitate a propellant quick-disconnect system capable of safely and reliably decoupling the fueling apparatus from the rocket during the launch sequence.

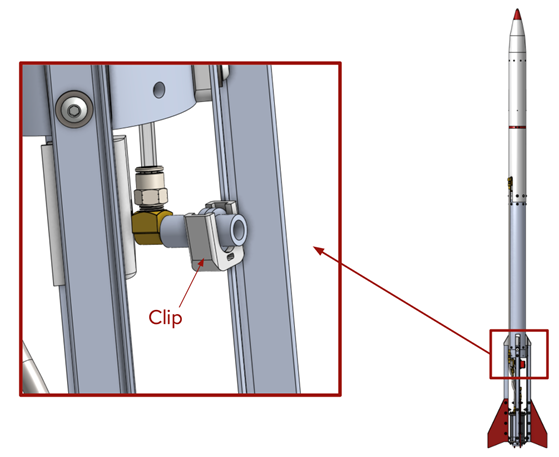

To address these challenges, Launch Lugs Ltd has developed a robust, portable quick-disconnect system with three primary components: a support structure, an actuation mechanism, and a fluid disconnection valve. Together, these components meet critical performance goals and safety standards while maintaining adaptability and cost efficiency:

- Support Structure: Designed for stability and precise alignment, the support structure is adjustable for various rocket sizes, launch configurations, and propellant systems. Constructed from steel for its high strength, durability, and affordability, the structure is lightweight and portable enough to allow for transport to remote launch sites.

- Actuation Mechanism: A spring-loaded linear bearing system retracts the fueling valve and electronics to protect them from rocket exhaust heat during launch. This mechanism ensures rapid and reliable disconnection, minimizing propellant boil-off and mechanical failure risks.

- Fluid Disconnection Valve: Featuring an actuated bayonet connector with a motorized twist-lock mechanism, the valve is engineered for high-pressure applications. For prototyping, the team utilized an off-the-shelf ball-latching disconnect valve actuated by a linear solenoid, balancing cost and reliability.

The system’s performance goals include filling 122 fl. oz. of liquid oxidizer within 60 seconds and enabling remote propellant tank drainage in the event of a launch abort. It is designed to operate in challenging environments, including extreme temperatures, wind, and dust, with a total system weight under 200 lbs. Material selection prioritizes UV stability, corrosion resistance, and durability to ensure a lifespan of at least 50 launches. Comprehensive testing, including pressure, leak, and functionality tests, underpins the system’s reliability and safety.

The Launch Latch system sets a new standard for collegiate liquid rocketry by combining technical innovation with practical implementation. By offering a remotely operable, highly adaptable fueling solution, it mitigates risks associated with pressurized propellants, reduces environmental impact through controlled detanking, and enhances the overall safety of rocket launches. This system supports WiSP’s broader mission to innovate in amateur rocketry and equip students with skills and experience to excel in aerospace engineering.

Full Technical Report Back to Home