Level 2 High Powered Rocket

Certification flight through Tripoli Rocket Association

Overview

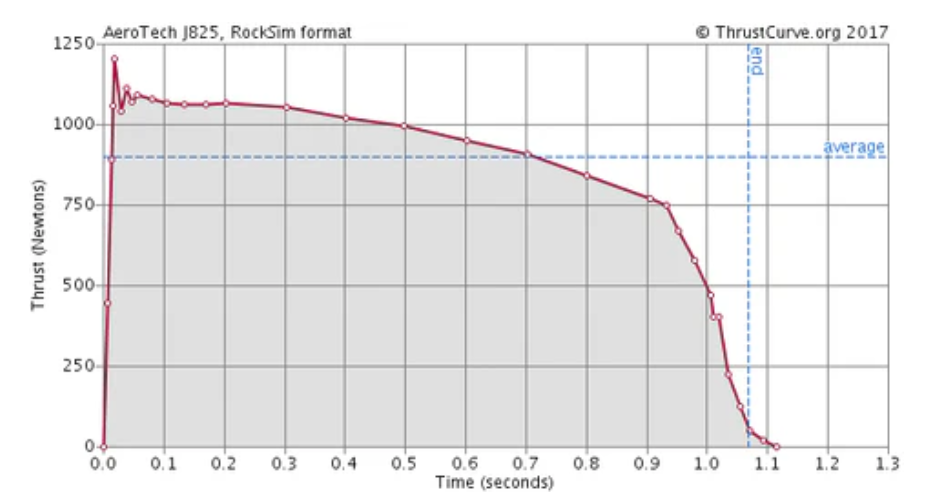

The Level 2 certification flight project undertaken through the Tripoli Rocketry Association aimed to design, build, and fly a high-power rocket whose total impulse fell between 640.01 N·s (J-class) and 5,120.00 N·s (L-class), satisfying all written and flight requirements outlined in Tripoli’s Unified Safety Code (TUSC) and FAA Regulation FAR 101.25. By demonstrating proficiency across structural design, stability analysis, and recovery‐system integration, the project not only served as an educational culmination but also as formal proof of operational capability at the Level 2 certification tier.

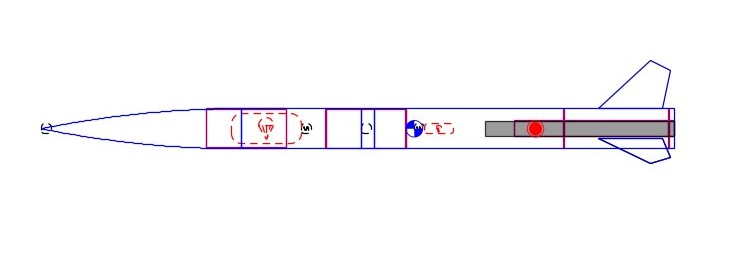

Mechanically, the airframe was configured around a 38 mm motor tube bonded to a 4″ body tube via precision centering rings, with three epoxy-mounted fins cut into the aft section to guarantee aerodynamic stability throughout ascent and descent. Each centering ring and bulkhead assembly was aligned and epoxied under tight tolerances, while shock-cord attachment points were carefully integrated into forward and aft bulkheads to ensure reliable dual-deploy functionality.

The avionics suite, enclosed within a forward avionics bay, comprised a Teensy 4.1 CPU for real-time control, a BNO055 IMU for attitude sensing, an altimeter for altitude telemetry, and an Apple AirTag for post-flight tracking. All components were powered by onboard batteries and logged to a Micro SD card. Flight software operated as a state machine, recording simulated thrust-vector-control outputs and sequencing drogue deployment at apogee followed by main parachute deployment at 200 ft, thereby validating system timing and data-logging capabilities.

Pre-flight analysis included detailed predictions of maximum altitude, range, and descent profiles calculated per Tripoli guidelines. These parameters were reviewed and approved by the certifying authority to verify compliance with TUSC and FAR 101.25. The certification process encompassed thorough motor inspections, nozzle-alignment checks, and in-flight observation, culminating in post-flight hardware examination to confirm vehicle integrity and recovery‐system performance.

Recovery employed a dual-deploy architecture featuring an 18 in drogue parachute sized via empirical equations and a 50 in main parachute selected for a 5–9 lb descent weight. Each was attached with appropriately rated Kevlar shock cords and shielded by fire-resistant cloth during ejection events. This configuration achieved safe touchdown velocities within Tripoli’s prescribed limits and provided robust redundancy against single-point failures.

Cost accounting tracked expenditures for the J192R motor, nose cone, altimeter, and recovery hardware, with avionics costs included while deferring thrust-vector-control hardware expenses to the dedicated TVC report. This ensured transparency and budgetary alignment with the project scope.

Full Technical Report Back to Home