Level 1 High Powered Rocket

Certification flight through Tripoli Rocket Association

Overview

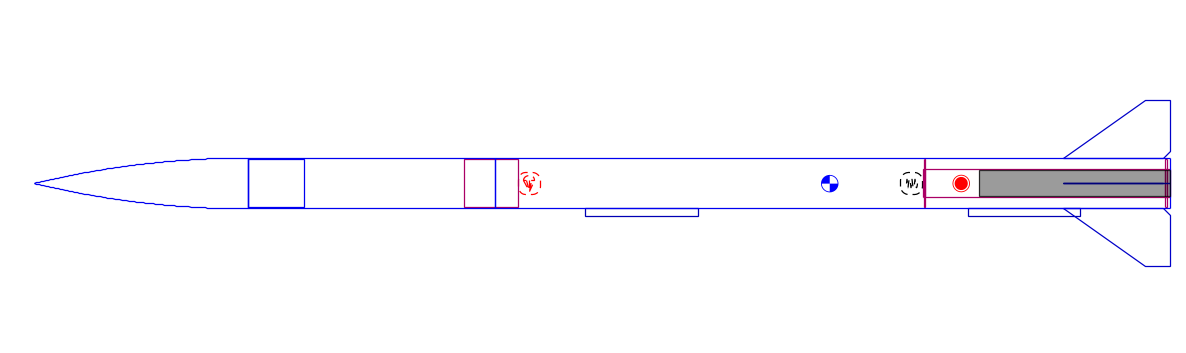

The Level-1 certification flight project began with a clear objective: to design, build, and fly a high-power rocket that satisfies all Tripoli Rocketry Association requirements for Level-1 certification. For this effort, I chose an Apogee Rocketry kit, which provided precision-cut airframe tubing, pre-slotted fins, a motor-mount tube, recovery hardware, and all necessary small parts. Before breaking out the glue, I modeled and simulated the entire rocket and its flight profile in OpenRocket, verifying static-stability margins, center-of-pressure vs. center-of-gravity location, and expected apogee altitude.

Tripoli Level-1 Certification Requirements

To earn Level-1 certification, Tripoli requires that the candidate:

- Propulsion class – Fly a commercially certified motor in the H or I impulse class (total impulse between 160.01 N·s and 640.00 N·s).

- Static stability – Demonstrate at least one caliber of static stability (distance between center of pressure and center of gravity ≥ one body-tube diameter).

- Recovery system – Equip the rocket with an adequate recovery system (typically a parachute) and demonstrate reliable deployment in flight.

- Flight performance – Conduct a successful launch and recovery under the supervision of a Tripoli-certified Range Safety Officer, achieving a stable, controlled flight.

The build process involved several key steps to ensure structural integrity and reliable flight performance:

- Motor mount installation: Epoxied the motor tube into the lower airframe section, taking care to align it perfectly along the central axis.

- Fin attachment: Glued each pre-slotted fin in place, faired the root and tip edges to the airframe, and applied fillets for structural reinforcement.

- Recovery harness and payload section: Installed the shock cord and parachute in the payload bay, anchoring the Kevlar harness to an internal bulkplate.

- Nose cone assembly: Epoxied the nose cone directly to the forward body tube, creating a seamless joint.

- Finishing: After full cure, applied a two-tone paint scheme for visibility; no streamer was used.

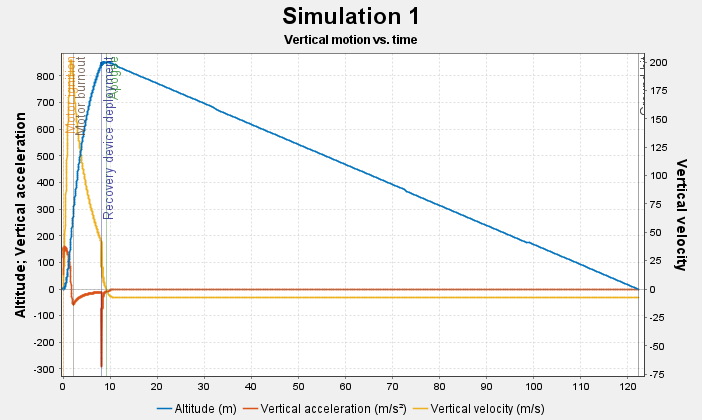

Before construction, I used OpenRocket to simulate the rocket’s flight profile and verify its design. The software allowed me to model the airframe, motor, and recovery system, then run virtual launches to predict altitude, velocity, and stability margins. These simulations confirmed that the rocket would remain stable throughout flight, achieve the required apogee, and deploy the parachute at the correct time—giving me confidence in both the design and the planned flight.

On launch day, the rocket was mounted on an 8 ft rail and ignited using an I-class motor. It lifted off cleanly, maintained perfect straight-up attitude, and reached apogee at approximately 1,200 ft—matching the OpenRocket predictions. At apogee, the parachute deployed flawlessly; however, high winds carried the rocket nearly a mile downrange before it was safely recovered intact. With all static-stability, motor-class, recovery, and flight-performance criteria met under the Range Safety Officer’s supervision, I was awarded my Level-1 certification that same afternoon.